For this project I decided to make some ethyl benzoate. Not only does it smell quite nice (in my opinion), but it can also be used as a building block or solvent in some organic reactions. My intention is to make benzoylated cellulose, a chiral stationary phase that was used in chromatography back in the day, but the outcome of this has yet to be determined. If you also decide to attempt this in order to try and make modified cellulose, it would probably be much easier to just buy methyl benzoate instead.

| Substance | M [g/mol] | n [mmol] | m [g] | V [ml] | Eq. |

|---|---|---|---|---|---|

| Benzoic acid | 122.12 | 1230 | 150.0 | – | 1.0 |

| Sulfuric acid (95%) | 98.07 | 270 | 27.5 | 15.0 | 0.2 |

| Ethanol (97%) | 46.07 | 8310 | 394.5 | 500 | 6.8 |

| Tetrachloromethane | 153.82 | – | – | 25 | – |

Experimental:

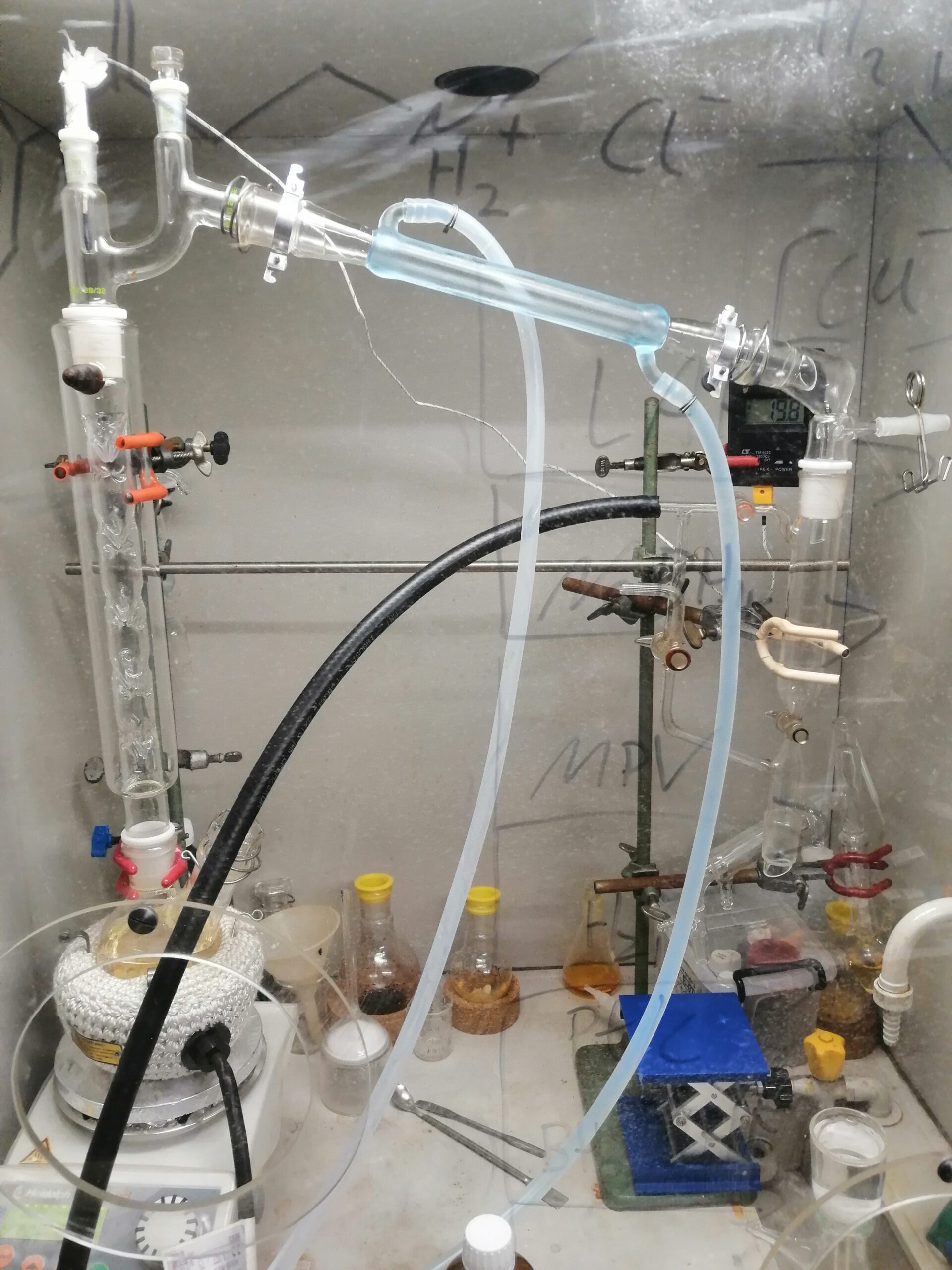

Into a 1000 ml round bottom flask was placed a mixture of benzoic acid (150.0 g, 1.23 mol, 1.0 Eq.), ethanol (97% in water, 394.5 g, 500 ml, 8.31 mol, 6.8 Eq.) and sulfuric acid (95% in water, 27.5 g, 15 ml, 0.27 mol, 0.2 Eq.), and a dimroth condenser was attached. After 5 hours of reflux with strong stirring, the remaining ethanol was distilled off by means of a rotary evaporator, and water (400 ml) was added. The mixture was added to a separatory funnel and shaken, which caused an emulsion to form. Addition of tetrachloromethane (25 ml) efficiently broke the emulsion and allowed for layer separation. The organic layer was washed with concentrated sodium bicarbonate solution (100 ml) and dried over magnesium sulfate. The tetrachloromethane was removed by rotary evaporation and the remaining liquid was fractionated, yielding a fraction with a boiling point of 89.6 °C at 19 mbar.

Clear iridescent liquid. Yield: 110 ml, 108.9 g, 60%. ND20 = 1.5065

NOTE: The mixture foams a lot to the point of being impossible to distill by the usual method. Adding a septum with a parafilm wrapped needle pointing into the distilling liquid in order to bleed air into the mixture significantly reduces foaming. Addition of 100 cst silicone oil also helps to some extent.

Adapted from: Vogel’s Textbook of Practical Organic Chemistry, 4th Ed., 1978, p. 841-842